Company

Blox

Year

2021

Roles

Modular Design

The Lean Approach

Working across both physical manufacturing and digital product design revealed a fundamental truth: efficiency comes from modularity. Whether building hospital infrastructure or design systems, the principles of minimizing waste and maximizing reuse create scalable, production-ready solutions.

+62%

in Efficiency

-21

of Unique Parts

Eliminating Waste Through Component Reduction

The core principle of lean manufacturing—eliminating Muda (waste)—translates directly to design systems. Just as physical products benefit from fewer unique parts, digital systems thrive when component counts are minimized. Each unique component requires:

Documentation and maintenance

Cross-functional coordination

QA and accessibility validation

Developer implementation time

Impact: More components mean more coordination overhead, slower velocity, and increased technical debt.

Designing for Multiple Configurations

The most efficient components accommodate multiple use cases without modification. This approach:

Reduces the total component count

Increases consistency across products

Accelerates implementation

Simplifies maintenance

Subassembly Architecture

Nesting Components for Maximum Value

Individual components gain power when grouped into subassemblies. Like Russian nesting dolls, complex interfaces are built from simpler, reusable parts. This creates:

Offline optimization: Complex patterns can be refined independently

Increased throughput: Teams work in parallel on different layers

Captured complexity: Sophisticated functionality packaged in simple APIs

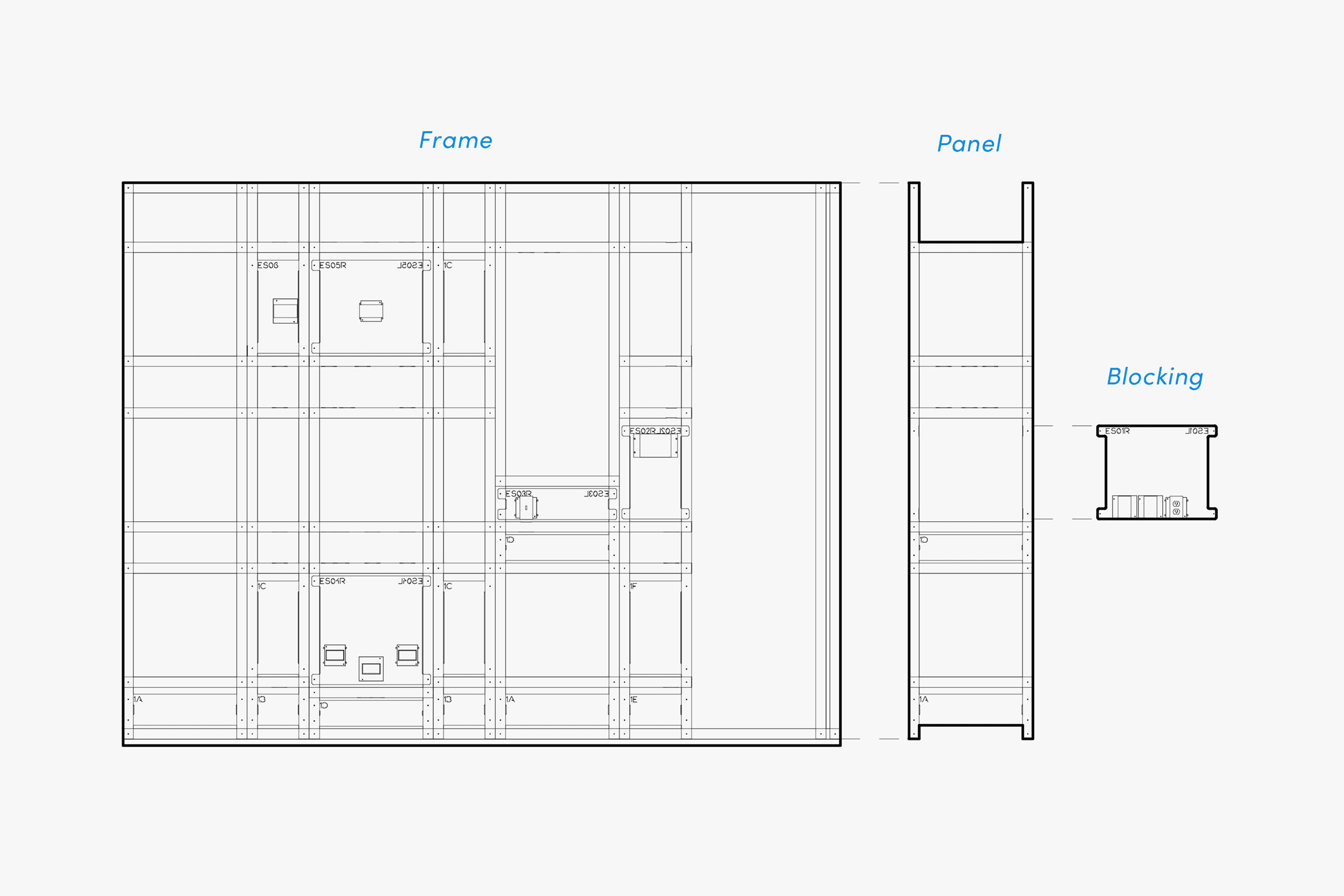

Real-World Application: The Hospital Headwall

Challenge: Design a structural frame for a hospital headwall supporting numerous electrical and plumbing devices while meeting code requirements and maintaining manufacturing efficiency.

Solution: Built on a standard 2×2 grid panel system, customized only where necessary. By using existing frameworks and repeating blocking panels:

Reduced unique parts from 34 to 13

62% increase in efficiency

Maintained flexibility for various configurations

Inherited proven manufacturing workflows

Translation to Digital Design Systems

Information Architecture

Organize components by type and nest related elements. This creates hierarchies that are:

Intuitive to navigate

Easy to maintain

Scalable as the system grows

Component Libraries

Maintain a design system where components are reused across contexts:

Maximizes individual component impact

Reinforces brand consistency

Reduces design and development time

Implementation

Well-structured component architecture means:

Code written once, debugged once

Referenced repeatedly across products

Faster feature development

Reduced maintenance burden

Key Principles

Minimize Unique Parts: Every additional component has downstream costs. Question whether new components are truly necessary.

Design for Reuse: Build components that accommodate multiple configurations rather than single use cases.

Create Subassemblies: Group related components into patterns that can be maintained and optimized independently.

Think Systematically: Your design decisions impact engineering, QA, documentation, and ultimately the end user.

Results

By applying lean manufacturing principles to design systems:

Faster product development cycles

Increased consistency across platforms

Reduced maintenance overhead

Improved collaboration between design and engineering

Scalable systems that grow efficiently

The closer design and development work together—seeing the full lifecycle from concept to production—the more opportunities emerge to validate ideas quickly and make decisions that truly serve users downstream.

Mork Work